OUR PACKAGING MACHINE EXPERTISE

We build Customized as well as standardized Packaging Machines Suitable for the Spices, Powders & Free flowing Proucts.

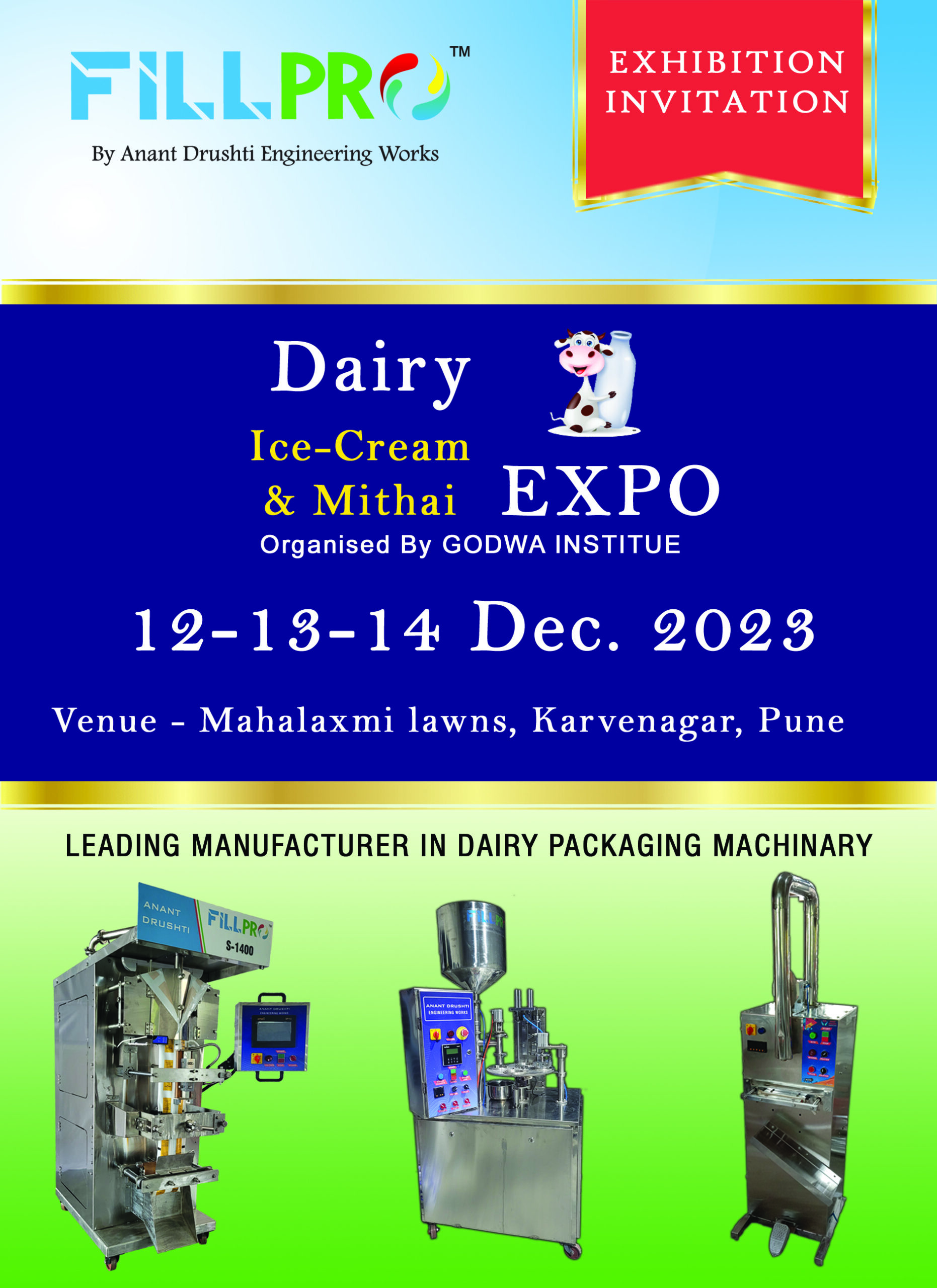

Dairy industry is our core Manufacturing Sector. Here, we have wide ranges of Packaging Machines from Small Dairy Outlet to Large Scale Dairy Manufacturing Industry.

We have Developed Various Packaging machines required for Paste Packaging Purpose. Our Machines are Suitable for Sachet Packing, Bottle Filling, Jars, Spouts Etc.

We design, Manufacture & Program, not just a Machine, but Total Solution which fulfils your Requirements.

Any Packaging Machine is used for increasing the production output. Hence our Machines are build reliable by using standardized production methods.

Our professional team has expertise more than 25 years in their field which results as most strong source of faithful clients.

After sales service is the key aspect for selecting any Manufacturer. Thus, our all Machines are assured with After sales service support which reduces downtime of the work.

This site is Protected. Obtaining Secure Connection.

Stay Connected.